| Key facts | |

| Product | DAMTEC® SBM K |

| System | Sub Ballast Mat |

| Thickness | 2x 23 mm |

| Installation | 1997 |

| City | Sembrancher |

| Country | Switzerland |

Project description

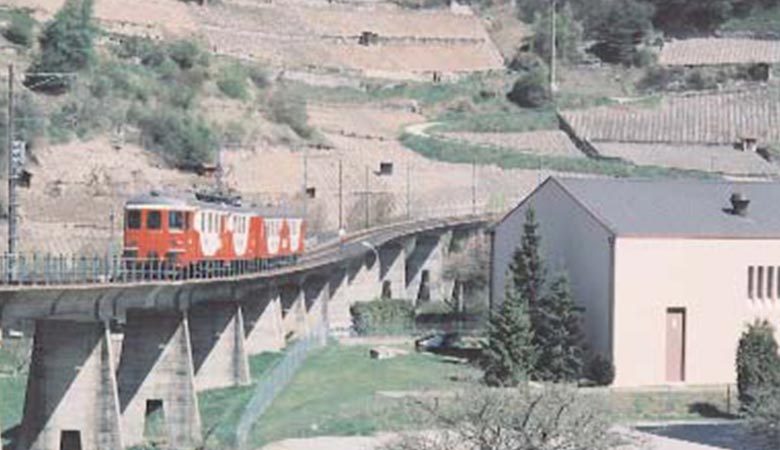

The viaduct in Sembrancher in the French‐speaking area of Switzerland was put into operation in 1952 and was originally used for transportation purposes during the construction of the dam at Barrage du Mauvoisin.

Later on, the railway line Martigny‐Orsiéres was extended and exclusively used for the transportation of passengers. Having suffered severe frost and weather influences, the viaduct was subjected to complete restoration in August 1997.

As a part of these building measures, the intention was also to counteract increase noise annoyance and a decision was therefore reached to install

KRAIBURG Sub Ballast Mat of the company Gummiwerk KRAIBURG Relastec GmbH.

Starting point

In order to be able to restore the viaduct carefully, the complete gravel surface was removed. This was followed by a new watertight layer being installed in order to prevent water penetration into the inside of the bridge and any damage to reinforcements as a result. This layer was not to be damaged by sharp gravel stones.

A purely protective layer was also discussed as an alternative to a KRAIBURG USM Sub Ballast Mat. However, as this section of track is subject to extremely frequent use and located in the immediate vicinity of some new residential blocks, it was necessary to do something about the increasing level of noise annoyance for residents. Consequently, the installation of undergravel mats which guarantee both a protection of the bottom layer as well as a reduction in structural sound was a logical choice.

The advantages of the DAMTEC SBM K can be summarized in brief:

• Protection of the sensitive sealing layer against damage from gravel stones

Reduction of structure‐borne noise

Reduction of secondary air‐borne noise

• Protection of the construction by reduction of vibrations

• Uncomplicated installation

Prognosis process and measurements

In order to be able to make a prognosis of the influence of the Sub Ballast Mat, measurements were first of all carried out by a sonic engineering office under instruction of STRAIL Verkehrssysteme / Gummiwerk KRAIBURG Elastik GmbH.

The insertion insulation size of the undergravel mat – which is decisive for the effectiveness of the Sub Ballast Mat, was determined in the laboratory for a specific structural design.

Following this and prior to commencement of the construction work, measurements were taken pursuant to DIN 4150 and DIN 45669 whilst a train was travelling past in order to establish the structure‐born noise level. Measurements were taken at two concrete pillars of the viaduct.

Two measuring points were located in the vicinity of the bridge which was fitted with steel sleepers. The other two measuring points were located in the vicinity of the bridge which was fitted with wooden sleepers. The steel sleepers were replaced with wooden sleepers in the course of the restoration measures.

A transfer function was now drawn up taking into account the existing outline conditions, making it possible to assess the benefit of the Sub Ballast Mat.

The calculations showed that the installation of DAMTEC SBM K would provide a significant improvement. Upon completion of the total construction work, measurements were taken again at the same point under the same conditions.

It is seen that the measured structure‐borne noise insulation corresponds very well with the prognosticated structure‐borne noise insulation. An exact correspondence of theory and practice cannot be expected. Furthermore, it can clearly be seen that the effectiveness of the Sub Ballast Mat is considerably worse at a frequency range of approx. 100 Hz to 250 Hz than in the other frequency ranges. The significant curve development in this frequency range depends on local conditions as well as the bridge structure and is not due to the behaviour of the Sub Ballast Mat as such. This is confirmed by laboratory measurements where no worsening was observed within this frequency range. Exchanging the steel sleepers resulted in an improvement of approx. 2 dB irrespective of the installation of the undergravel mats. The effectiveness of the Sub Ballast Mat with an upper gravel layer of 25 cm comes into play at a frequency of approx. 35 Hz. The result is a mean insertion insulation level of 13 dB. Consequently, a considerable improvement in structure‐born noise emissions was achieved through the installation of DAMTEC SBM K.

Installation

The Sub Ballast Mat were laid direct on the sealing layer on the surface of the viaduct at a thickness of 2 x 23 mm. A single layer of 1 x 23 mm was sufficient for the inclines.

An additional layer of fleece was laid as top layer in order to protect the undergravel mat against dirt and gravel abrasion and therefore guarantee in full the functionality of the Sub Ballast Mat for years to come. In addition, a covering section made of galvanized sheet metal was fitted to the upper edge of the inclines in order to ensure a clean finish.