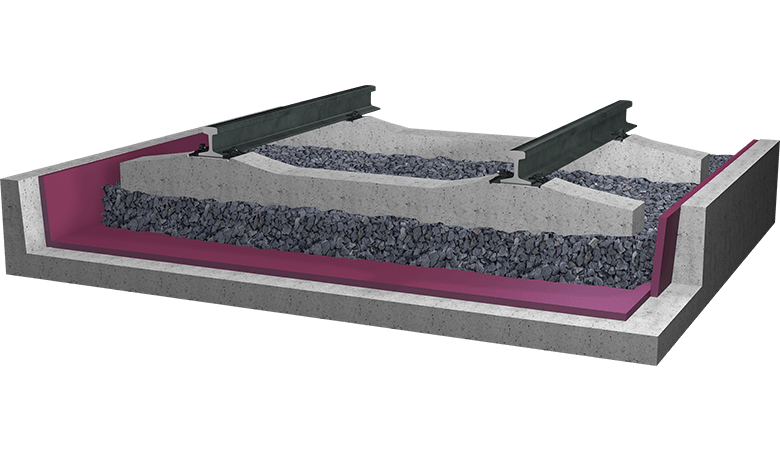

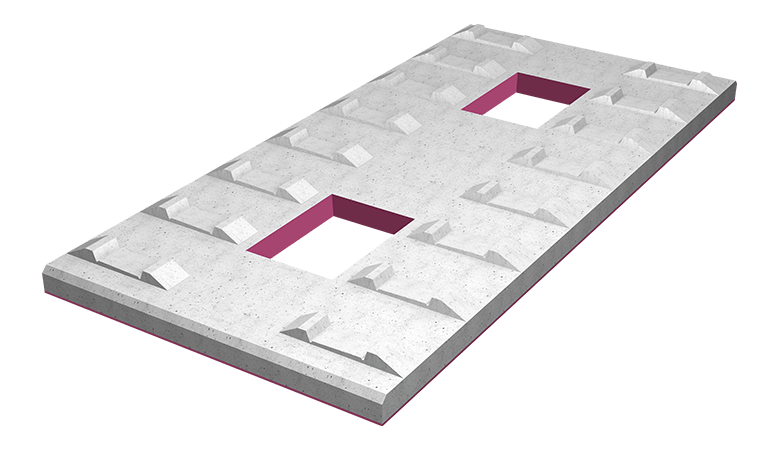

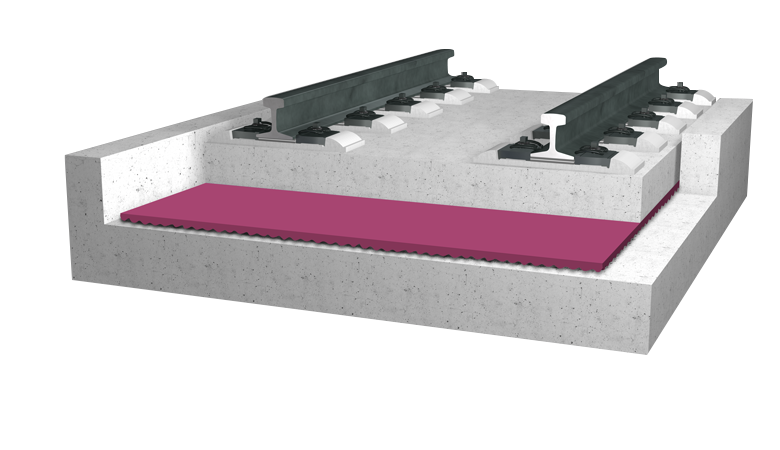

DAMTEC® MSS K – Full surface bearings for mass-spring systems

DAMTEC® MSS products are decoupling and protective mats under rail systems tested according to DIN 45673-7 (Mechanical vibration – Elastic elements of the superstructure of rail tracks). They reduce structure-borne and secondary airborne noise and vibration emissions when used in „slab track“ (mass-spring system).

DAMTEC® MSS products are supplied in rolls. Mats are available on request.

Products:

- DAMTEC® MSS K 10

- DAMTEC® MSS K 20

- DAMTEC® MSS K 23

Products with wave cut profile:

- DAMTEC® MSS K 17/8

- DAMTEC® MSS K 25/7

Advantages and properties of DAMTEC® MSS K products

reduce secondary airborne sound

keep track position stable for longer period of time

protect adjacent structures by reducing vibrations

environment-friendly

extremely economical

easy installation

low water absorption

extremely durable

reduce the transmission of structure-borne sound

FAQs regarding DAMTEC® mass spring systems

What material are DAMTEC® MSS K products made of?

DAMTEC® MSS K products consist of a special mixture of PU foam and high-quality recycled virgin rubber granules with a PU elastomer bonding agent i. e. from unused new raw materials. This leads to the desired properties and takes environmental protection into account. An aging of the rubber granulate is thus excluded. In particular, used tyres are not used here. With the extensively tested formulations, the products meet special requirements resulting from the loads in the track area. These elastomer materials are also used in other demanding areas such as building construction, civil engineering and tunnelling. Particularly noteworthy is the long-term behaviour, which guarantees a constant high level of effectiveness over decades. In this way, they efficiently counteract the multi frequency vibrations and shocks that are transmitted to the environment.

What does DAMTEC® MSS K stand for?

The term is an abbreviation of the following words:

Mass

Spring

System

Kautschuk (rubber)

In what form is DAMTEC® MSS K delivered?

The bearings for mass-spring systems are supplied as standard in 1,250 mm widths as rolls. Depending on the thickness, different roll lengths are available. Slabs or other lengths can also be produced for certain project requirements.

How are DAMTEC® bearings for mass spring systems installed?

You can find detailed installation instructions in our download area.

How many years have DAMTEC® bearings for mass-spring systems been on the market?

We realized our first reference project “Viadukt Sembrancher” in Switzerland as early as 1997, so we can look back on more than 20 years of experience in the railway sector. To date, we have successfully supplied products for sound and vibration insulation to numerous major projects such as the Wiener Linien, the tram in Graz, the Butler Extension in Perth (Australia) or the metro in Kuala Lumpur (Malaysia).

How does the DAMTEC® Team support me in my railway project?

Solution Development & Detailed Solutions

Our many years of experience and our know-how with products for acoustic and vibration reduction are a guarantee for the solution of even very complex problems. Together with you, our specialists will develop effective systems to eliminate or minimize disruptive factors in the problem areas. In addition to standard solutions based on experience, we are of course also technically and personally in the position to implement completely new solutions, exactly adapted to your requirements.

Calculations, simulations and efficacy forecasts

To find out how effective measures can be in dealing with an emission problem, you don‘t have to wait until they are implemented. After a first inspection and analysis of the conditions on site, our specialists are able to create a calculation model in which all relevant factors regarding vibration and damping behaviour with different material properties are taken into account. This results in a realistic simulation that allows fine-tuning of these factors and enables our specialists to develop the optimum solution. At the end of the planning phase, you will receive proof of the expected effectiveness of the system. This efficacy forecast gives you the assurance in advance that your expectations will be met successfully.

Our services at a glance

- material testing and measurement on our own large scale test bench

- project support from the beginning

- installation advice and site support

- preparation of installation plans

- vibration-technical, mech. measurements

- solution development

- calculation and simulation

- efficacy forecasts

Technical terms - simply explained!

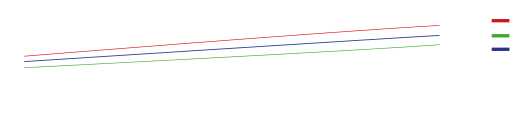

Static bedding modulus

With bedding theory, the track is imagined as an infinitely long rod that is laid on a continuous, elastic base. The bedding modulus is the elasticity value of the whole system, rail – railroad tie – ballast – substructure – substrate, and is used to estimate the static deflection of the operating load. This quantity is a measure of the stiffness that must be determined experimentally. The static bedding modulus basically indicates how deep the rail sinks under slow traffic conditions or a stationary train.

The bedding modulus is the ratio of the stress to the deflection. Usually, the secant modulus is measured, for example, between 0.02 N/mm² and 0.10 N/mm² . Alternatively, the tangent modulus can be determined.

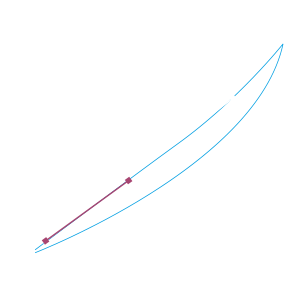

Deflection

A distinction must be made between the deflection and subsidence of the elastomer and the rail deflection. The deflection can be determined using the spring characteristics and is the distance in millimetres by which the material is compressed under a certain tension.

The rail deflection when in use takes into consideration the stiffness in the track superstructure from the vehicle to the substrate. It is calculated statically for the stationary and dynamically for the moving train. Depending on speed, axle load, superstructure type, sub-type and DAMTEC® type, the deflection is usually between 1 mm and 3 mm.

Dynamic bedding modulus

A distinction must be made between the low-frequency (superstructure dynamics) and the high-frequency dynamic bedding modulus (damping of structure-borne noise). With the first-mentioned characteristic value, the bending deformation of the rail under the rolling wheel can be estimated from the interaction of bending elasticity of rails and railroad ties, including ballast.

The higher-frequency dynamic bedding modulus of a ballast mat influences the natural frequency of the elastically mounted superstructure as a vibratory system as a whole and thus the insertion loss. The test is performed with a static preload.

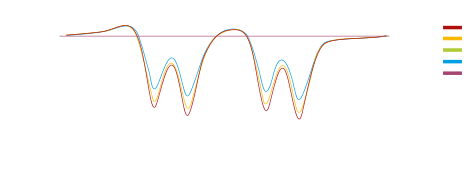

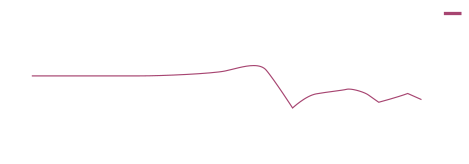

Insertion loss

The insertion loss ΔLe (in dB) is a characteristic value that expresses the extent to which inserted measures contribute to reducing the structure-borne noise introduced into a system. The insertion loss ΔLe is the ratio of the structure-borne sound power “without installed measures” to “with installed measures”. It is a characteristic value of the entire system – from the vehicle to the substructure.

Forecast calculations

Since the mechanisms for the generation and propagation of structure-borne sound associated with rail transport are widely known, the expected effect of mitigation measures can be calculated in advance after a thorough evaluation of the system in the way they are to be used. There are many tried and tested calculation models available for this purpose. The combination of advanced materials that meet all modern requirements for effective sound and vibration protection, as well as the vast experience in implementing more effective measures make DAMTEC® the ideal partner for sound and vibration reduction in the railway sector.