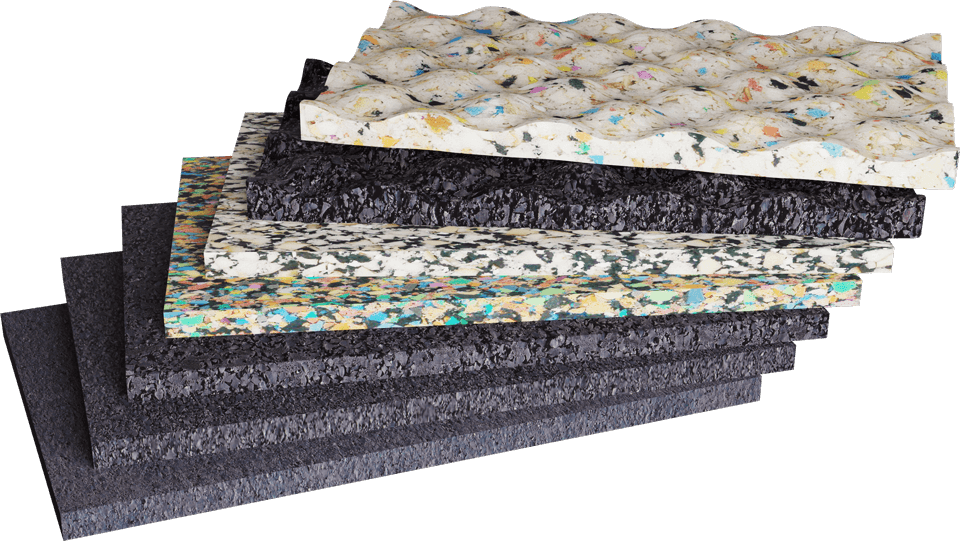

KRAIBURG Relastec DAMTEC® has specialised in the manufacture of construction bedding materials for decades. They are competent partners for vibration isolation products made of recycled rubber granules and for determining the most effective sound insulation measures. No one wants to have their well-needed rest disturbed by noise on stairs, loud washing machines, stereos or vibrating machines next door. There is now a solution: elastomer springs of the DAMTEC® vibra and DAMTEC® vibrafoam series are two timetested product lines and recognised techniques for reducing these problems.

This is achieved with elastic beddings of polyurethane foam and recycled rubber granules, which enable the soft and elastic bedding of all building components, similar to shock absorbers and springs in the construction of cars. The load transmission is limited to the elastomer bedding. Both product lines offer the ideal solution for any requirement, including foundations for heavy-duty machinery, smaller stairways, large-surface floor constructions or the insulation of an entire building.

Different material densities, hardnesses, thicknesses and geometric shapes adapt to the requirements for light or heavy weight situations. The focus is on choosing the right product, which means an exact analysis of the physical conditions of the actual vibration problem. After all, a car needs a lighter shock absorber than a truck – and an ideal solution requires precise and detailed coordination of the individual problem.

Therefore, the product portfolio of the DAMTEC® vibra and vibrafoam series offer the ideal “springs and shock absorbers” for virtually every application. Our engineers help you choose the right material and measure the elastic support individually

based on your specifications.

Especially important is the new approach of adapting the construction based on the excitation frequencies and the existing loads. The goal of this process is to achieve the best insulating properties. Also, resonant frequencies of the insulating mat and the excitation frequencies of the source of the vibrations are matched. This avoids the use of materials that are too soft or too hard.

Vibration Isolation made from recycled rubber

DAMTEC® vibra 30

compressive stress:

0.03 to 0.07 N/mm²

DAMTEC® vibra 50

compressive stress:

0.05 N/mm² to 0.15 N/mm²

DAMTEC® vibra 100

compressive stress:

0.10 N/mm² to 0.30 N/mm²

DAMTEC® vibra 170

compressive stress:

0.17 N/mm² to 0.70 N/mm²

DAMTEC® vibra 280

compressive stress:

0.28 N/mm² to 1.50 N/mm²

DAMTEC® vibra 700

compressive stress:

0.70 N/mm² to 3.00 N/mm²

DAMTEC® vibra 1500

compressive stress:

1.50 N/mm² to 4.00 N/mm²

Vibration Isolation made from polyurethane foam

vibrafoam and vibradyn

![]()

PURASYS offers effective protection against vibration and shock. PURASYS vibrafoam. This high-tech PUR elastomer can be placed as an isolating, area mat between the structural components, as cut sections matching the relative structural component geometry, and also as a tailor-made moulded part. We can offer you a wide program of 13 standard materials and the facilities for the production of special types in various colours and thicknesses according to your requirements.

PURASYS vibrafoam SD (formerly Dipoelast) is used for highly efficient vibration isolation and as protection against vibration. 13 types provide complete coverage for the static load range from 0.01 – 1.9 N/mm².

![]()

Elastic bearings of buildings, whose foundations come into contact with groundwater, are particularly problematic and can only be realized with special elastomers. KRAIBURG PuraSys now offers an alternative to the few available products on the market from other manufacturers. PURASYS vibradyn was specifically developed for such high demands.

PURASYS vibradyn, the closed-cell PUR product for highly effective vibration isolation, can be used in application areas such as building isolation, including in groundwater – in a static load range from 0.075 – 1.5 N/mm². PURASYS vibradyn has nearly no damping effect, and functions like a technical spring. It is ideal for use in situations where vibration isolation is subject to stringent dynamic specifications.