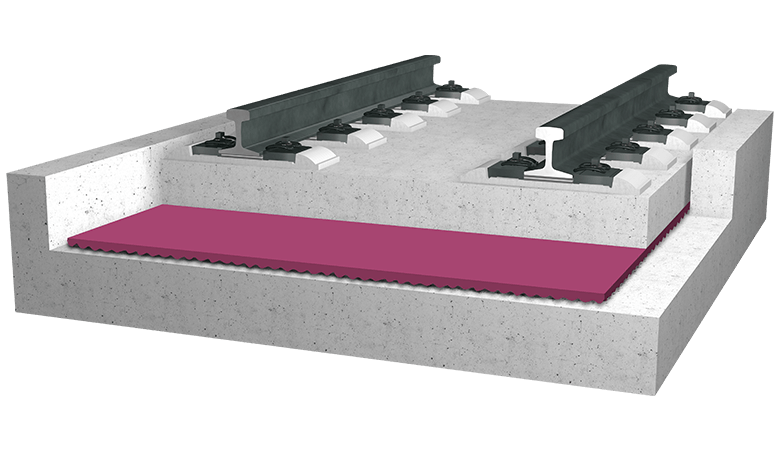

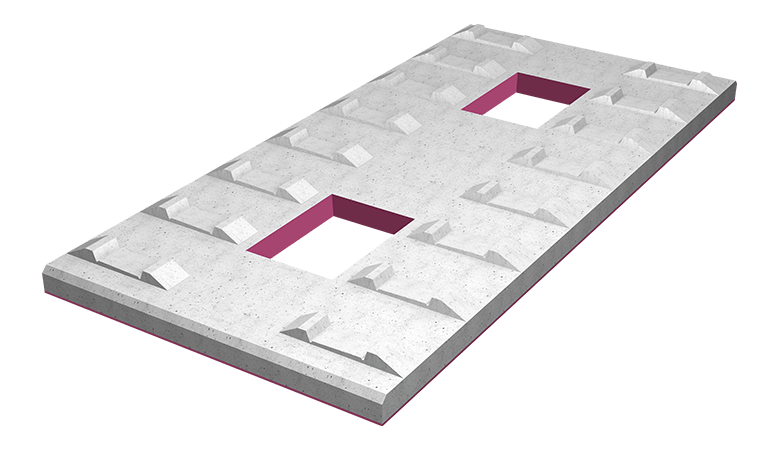

KRAIBURG Relastec, as part of the KRAIBURG Holding, specialises in sub-ballast mats and bearings for mass-spring systems with its

DAMTEC® division. KRAIBURG Relastec has already established itself through numerous international projects with its DAMTEC® products and offers its partners an extensive range of solutions to reduce noise and vibration problems in rail traffic.

DAMTEC® products have been tested in recognized external testing institutes and internally for the sometimes very demanding, project-specific conditions and specifications. It goes without saying that KRAIBURG Relastec is ISO 9001 certified and thus guarantees consistently high quality and complete traceability of its products. DAMTEC® products are tested according to DIN 45673-5, DIN 45673-7 and other national standards.

Quality products – produced in harmony with nature

Environmental protection is a key strategic task at KRAIBURG Relastec. We are fully aware that sustainable growth is only possible if we live up to our commitments and responsibility for environmental protection. That`s why KRAIBURG Relastec has a consistent course here: environmental protection is our daily program!

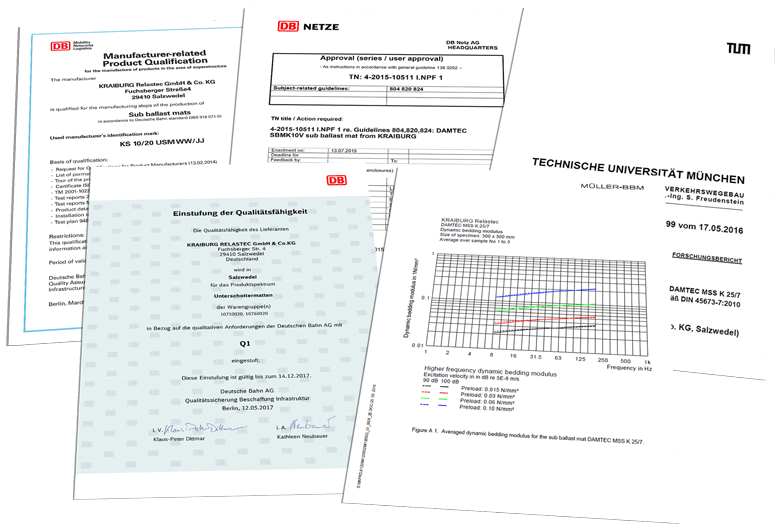

Manufacturer-related product qualification (HPQ) and Q1 certification at Deutsche Bahn AG

KRAIBURG Relastec has been awarded the „Manufacturer-related Product Qualification (HPQ)“ by Deutsche Bahn AG and the „Supplier`s Quality Capability“ is classified as Q1 for the product range of sub-ballast mats by Deutsche Bahn AG (DB AG).

The HPQ qualifies a manufacturer to produce a particular product using specific processes already described in standards, drawings or other technical documentation. It is required every three years for the annual Q1 certification.

The Q1 certification is the classification of a company, which is audited within the scope of DB AG‘s supplier management with regard to quality capability. As a Q1-supplier of DB AG, one is authorised by the client DB AG to supervise prefabrication services on one‘s own responsibility. Project-related external production approvals are no longer mandatory.

Our sub-ballast mats comply with the technical delivery conditions and are approved for use in the DB AG network (according to DBTL 918071 and e. g. TM-2015-10511 LNPF 1).

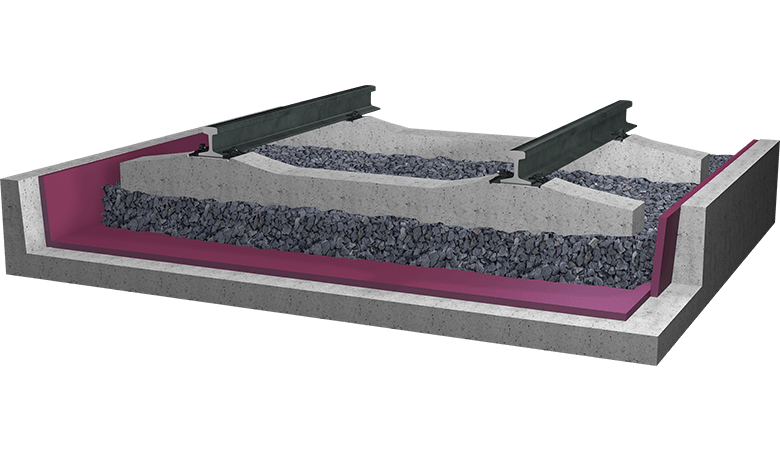

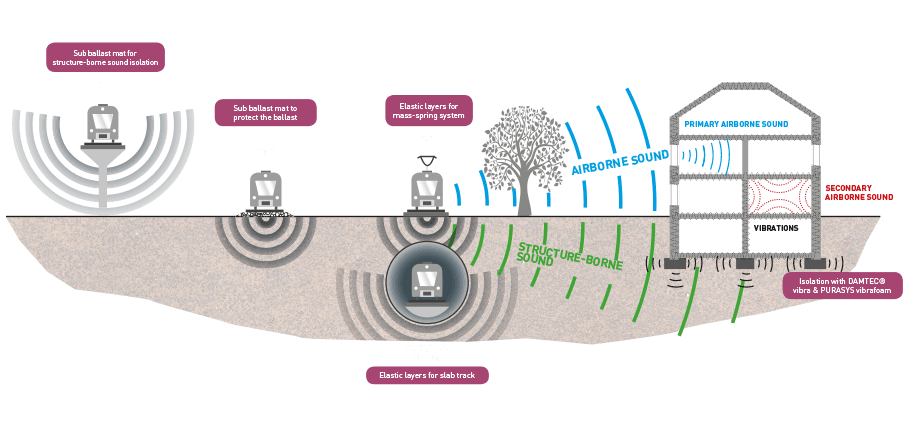

Sound sources / noise sources from railway transportation – structure-borne sound / airborne sound

Railway vehicles generate rolling noises and vibrations during operation. This is due to roughness and imbalances on both the wheels and the rail running surfaces. Surface defects such as head checks, corrugations and slip waves on the rails are known to be among the most common sources of interference.

These vibrations are transmitted to the ground via the roadway and spread as structure-borne noise. If buildings are located along or near the track, a transfer is also carried out via their foundations. The buildings begin to vibrate and, with the appropriate intensity, they are also preceived by humans as perceptible vibration or disturbing noise. Another consequence of this transmission chain is the emission of vibrations from building parts, e. g. ceilings and walls, to the environment. This takes place via the air, which begins to vibrate itself and then become audible as socalled secondary airborne sound.